Aptean – ERP system for process and manufacturing in the food and beverage industry

Are you looking for a standardized ERP that can handle your unique challenges in the food industry? Aptean is a complete end-to-end solution in the cloud that is built on Business Central and fully integrated with Microsoft Dynamics 365. Together, we'll take your business to the next level.

This is Aptean Food & Beverage ERP

Aptean Food & Beverage ERP is a standardized industry solution for all companies in the food industry. The system is based on the latest Microsoft technology, known as Microsoft Dynamics 365 Business Central. When you invest in a Microsoft strategy, you have a fast track to integrations, for example, IoT, Data Management, and AI.

A selection of what Aptean gives you access to:

- Process automation

- Supply Chain Management

- Quality & food safety processes

- Data Exchange Framework / EDI

- Administration, purchasing, and sales

- Consignment Management

- Business Intelligence

An industry solution that understands your challenges

We understand your industry and see that the food and beverage industry is becoming more complex and competitive every day. Companies are struggling to keep up with the ever-changing demands of consumers, new safety regulations and active sustainability efforts while still having to run the business at a profit.

An integrated and industry-adapted ERP system like Aptean ERP will play a crucial role in helping you and your company succeed in particularly challenging times.

If you work with perishable products such as meat, fish or fruit and vegetables, your ERP system must have a high level of reliability and be able to handle high transaction volumes and fast flows. In addition, it should be easy to scale up and adapt the system to support the growth of the business, as well as ensure the handling of specific cases such as:

- Quality control

- Traceability and batch management

- Special Pricing Models

We know what's important to you today and what you need to do to stay competitive in the future.

Aptean for Business Central is the recipe for success!

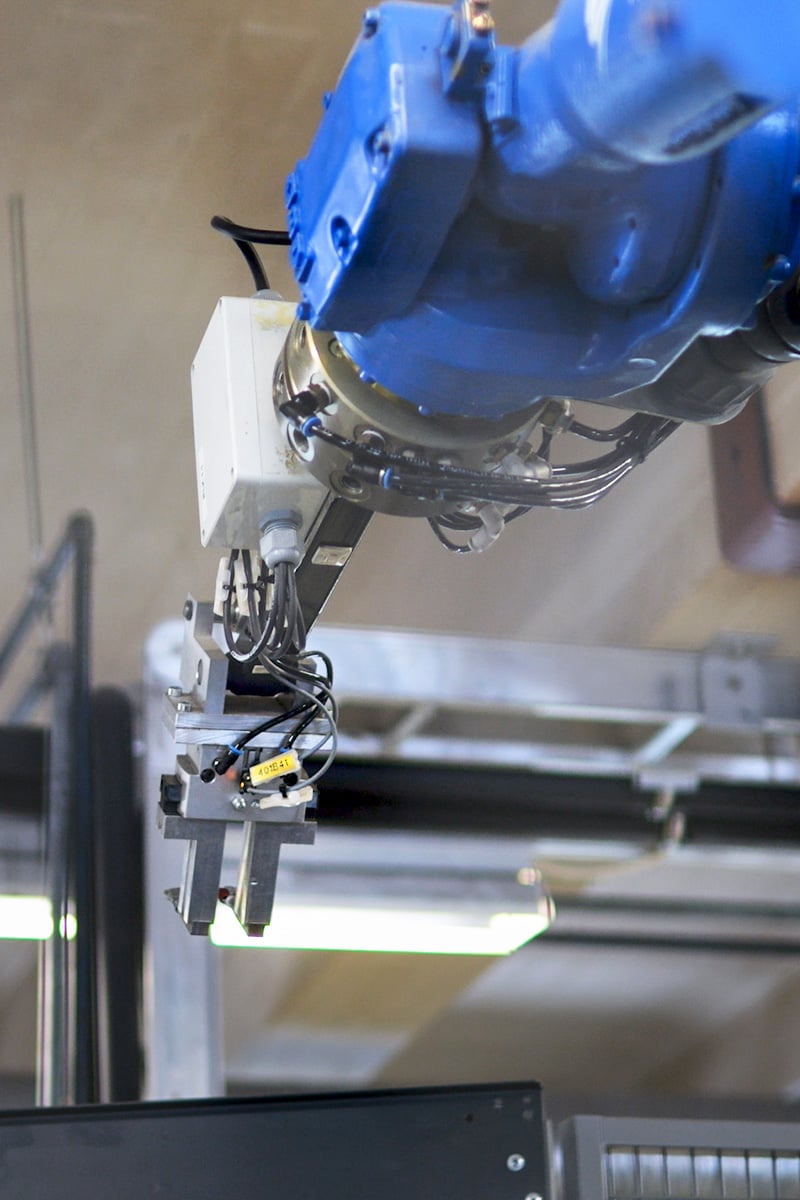

Efficient and safe production

If your offer is not in line with your customers' wishes, profitability will suffer. A temporary lack of attention to security controls can result in downtime or worse. Without full visibility of the ingredients you're using, you run the risk of unlabeled allergens ending up where they shouldn't.

For your business, successfully handling all of these issues will require agility, flexibility, and versatility, especially if your products cross borders and ship worldwide.

Tailor-made solutions for every area

The food industry has to overcome special challenges every day. From automated and centrally controlled production processes to flexible adaptation to the requirements of retail chains, to permanent quality controls and smooth traceability. No matter whether meat, fish, baked goods, or fruit and vegetables, Aptean Food & Beverage – Foodware Edition offers the right technology for the different challenges of the individual sub-sectors in the food industry.

Meet customer needs better and faster in the meat sector

Every industry has its challenges, but one of the biggest global challenges is nutrition and the ability to continue to feed our population. There are special challenges in the meat sector, all of which ultimately take into account the need to meet consumers' needs even better and faster.

- Transparency: product specifications

- Disassembly and cutting efficiency

- Numerous end products

- Food control and safety

- Short order cycles

- Weight items

- Animal welfare and sustainability

- Insights into management information

Quality and safety in the seafood industry

There are several industry-specific issues at play in the seafood industry. Sustainability, short-order cycles, and cutting efficiency are perhaps the most common challenges facing the seafood industry.

- Traceability

- Cutting efficiency

- Food Safety & -quality

- Daily forecast

- Rapidly changing market

- Protection against overfishing

- Insights into management information

Have a full overview of your products

In the area of fruit and vegetable products, specific challenges continually arise with the aim of meeting consumers' needs better and faster. Because ultimately, the consumer determines the market.

- Margin

- Game management

- Origin

- Demand forecast

- Food quality

- Value creation

- Supply chain alignment

- Monitor costs

- Packaging overview

- Fast processing

Maintain a complete overview of your dairy product production

The dairy sector faces challenges typical of the industry that require specific software functionalities. Take cheese production, for example, a really specific discipline due to the fact that the cheese can dry out during maturation. But silo management and fluctuating prices should also be taken into account. One thing is certain: this diversity brings with it special challenges in this turbulent market.

- Fluctuating milk prices

- Various end products

- Food control and safety

- Animal protection

- Insights into management information

Innovation and flexibility for the bread and baked goods industry

At the heart of the challenges in the highly competitive market of the bread and baked goods industry are constantly changing requirements that require flexibility. These changes require innovation and more flexible production capacity from many industrial bakeries. This is the only way they can efficiently produce multiple types of products to respond to newer trends. Customers expect freshness, selection and quality.

- Food safety

- Inventory management and planning

- Effective production processes

- Reduction in reject rates

- Labels

- Daily forecasts

- packaging

Maintain quality in the confectionery industry

The challenges of the confectionery industry force manufacturers to solve a variety of problems to ensure that not only high-quality products are produced under the best conditions, but also that they are delivered to their consumers in the shortest possible time. From traceability to data collection, challenges are widespread in the confectionery industry.

- Health concerns

- Food safety and quality

- Traceability

- Flexibility in the supply chain

- Avoiding recalls

- Performance of the production lines

- Packaging materials

- Quality controls